Interestingly, one of the main limiting factors for the development of promising technology industry – three-dimensional printing – are patents. Yes, yes, those patents that allow some companies to prohibit competitors produce all rectangular with rounded corners.

But, fortunately, there is good news from the bureaucratic front – in February 2014 the validity of several key patents that prevent the development of 3D-printing industry, will expire, according to Duane Scott (Duann Scott), an evangelist of the company Shapeways, which produces models for 3D -printers under the order.

But, fortunately, there is good news from the bureaucratic front – in February 2014 the validity of several key patents that prevent the development of 3D-printing industry, will expire, according to Duane Scott (Duann Scott), an evangelist of the company Shapeways, which produces models for 3D -printers under the order.

According to him, patents are prohibited from using all comers technology called “laser sintering”, the most advanced three-dimensional printing technology in terms of price / quality ratio. Laser sintering technology, thanks to the high resolution in all three dimensions, outputs the resulting high quality product, the product can be used as the final prototype or even sell as a finished product, without further treatment.

Among Duane used a lot of industrial machines for three-dimensional printing, however, afford such a car, “a mere mortal” virtually unable to – the cost of industrial machines is several tens of thousands of dollars.

A huge drop in prices and a flurry of low-priced Chinese of 3D-printers

“With the expiration of key patents that describe the three-dimensional printing via laser sintering, we will see a huge drop in the price of similar devices” – says Scott. And this is not just idle speculation – there are already good examples.

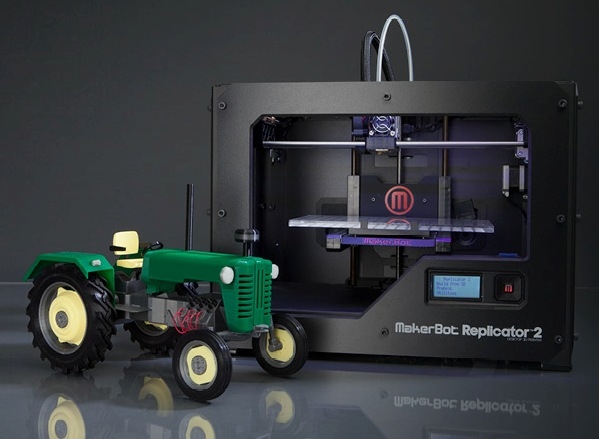

One such example was the company Makerbot, the expiration of patents on getting a more primitive technology of three-dimensional printing, known as the “simulation by overlaying» (fused deposition modeling or FDM) and FDM-created the cheap printers for home enthusiasts and modellers.

Interestingly, the recently Makerbot was acquired from the giant field of three-dimensional printing – the company Stratasys (the founder of which, ironically, is the inventor of the technology FDM). Makerbot was bought for $ 400 million plus the bonus shares in the amount of 200 million.

Interestingly, the recently Makerbot was acquired from the giant field of three-dimensional printing – the company Stratasys (the founder of which, ironically, is the inventor of the technology FDM). Makerbot was bought for $ 400 million plus the bonus shares in the amount of 200 million.

After a relatively short period of time after the expiry of patents on the technology FDM, the price of printers that use this printing technique, dropped from tens of thousands of dollars to just $ 200-300. This has led to the emergence of a community of people who are keen amateur modeling, to get their hands a tool for creating virtual copies of material models.

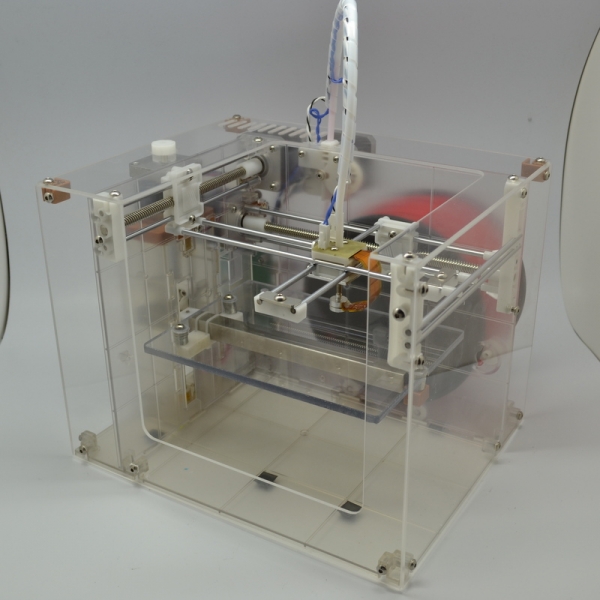

Cheap printer dvuhsotdollarovy MakiBox A6 LT

Cheap printer dvuhsotdollarovy MakiBox A6 LT

The consequences of the fall of the barrier in the form of protection of the rights of patent holders have increased competition (which is always good), three-dimensional printing technology popularization and, of course, as a result, the depreciation of produced devices for consumers – the same fate awaits the more promising technologies, says Scott from Shapeways.

“This has already happened with FDM – and it will be laser-sintering. Once the patents expire, users will overtake the new wave of available printers, and the technology will be open. Just look at the hundreds already sold FDM-machines, which cost from $ 300. But just five years ago such devices is in the $ 14,000, “says Duane.

What is most interesting, a lot of cheap three-dimensional printers today are produced from … guess where? That’s right, in China. Where else!

In addition to the rapidly growing community of fans of the “home” three-dimensional printing, and there are major shifts promising technology in the industry and knowledge-intensive industries: recently we wrote about space agency NASA, who decided to publish parts of engines for 3D-printers. And the same China (represented by the Ministry of Industry) last year allocated $ 32 million for the introduction of three-dimensional printing technology research centers in the country.

The quality of industrial 3D-printing – at home

Many critics who are watching the topic, do not account for one thing – not all three-dimensional printers are the same. Not all printing technologies allow today to get the same quality “prints”. This is especially true for low-cost 3D-printing.

Today’s cheap three-dimensional printers are suitable for creating models that make it clear how the subject will look in the material world – the subject can touch and rotate it in his hands, as well as, for example, show the customer. However, the model will not be permitted for the final prototypes or create forms for further mass production by conventional casting. And even more, such models can not be positioned as a finished product that you can sell to the consumer.

With the expiration of patents on the technology of three-dimensional printing by laser sintering state of affairs, according to the same chaperone, will change drastically.

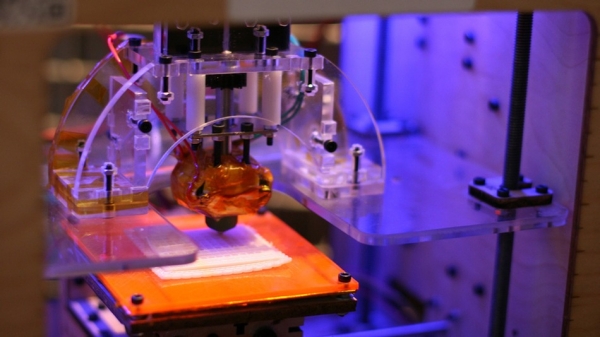

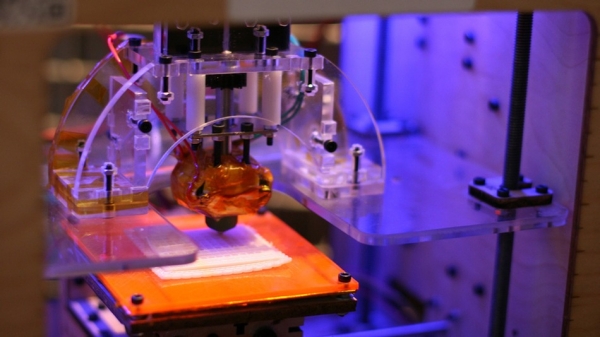

Industrial printer EOS Formiga P 100

Industrial printer EOS Formiga P 100

At the moment, designers have developed a virtual model and want to translate it into reality, have to order it “printing” companies like Shapeways. But the problem is that companies like Shapeways currently very busy work – they are crazy popular and just not be able to buy a sufficient number of printers using the technology of laser sintering, resulting in a two-week waiting orders.

Another industrial printer EOS – Eosint P 395

Another industrial printer EOS – Eosint P 395

And it’s not that at the same Shapeways is not enough money for new 3D-printers. The fact that the manufacturer of printers, which are used in Shapeways, there is no way to sell new printers – the line of customers stretched for 12-18 months in advance!

The expiration of key patents will be a big step forward and will lead to an influx of a large number of low-cost three-dimensional printers in the consumer market. These printers are not only affordable, but will produce low-cost, high-quality prints comparable to the mass-produced products.

It remains only to wait a year or two, and who knows, maybe quality of 3D-printers will get every tenth our readers.

Read another very interesting article about alternative energy of the Sun, water and air.

Muchas gracias. ?Como puedo iniciar sesion?