Plastics are versatile organic materials, which are used in almost all areas. Suffice it to recall the tablets and smart phones, the vast majority of which are made in plastic cases. Plastic is lightweight and inexpensive. In addition, the products of it simply into any shape. Plastic enclosures currently have only one drawback – the strength. Most consumers complain of cracks and chips on the body after the fall of devices. Development of researchers from Duke University in the United States may soon eliminate this drawback.

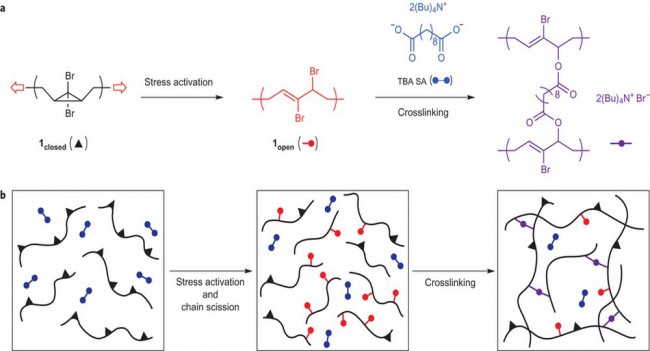

According to them, at a certain impact plastic is becoming stronger. To make it stronger, you need to make changes at the molecular level. Established researchers material as conventional plastic, has a matrix of carbon, but in this case its atoms arranged in a triangle shape and form long chains with two bromine atoms in one point. Scientists have found that this structure converts the destructive burden of deformation in the binding energy. If the data chains efforts, they break on only one side, whereas in other types of similar interference plastic lead to complete destruction of the structure. But this is only the first stage of transformation. Shear force breaks the triangles on a long chain and frees up space for the entry of a second molecule of bromine. Fill binding sites for a new type of plastic molecules, the researchers decided carboxylate. They allow you to connect several chains and increase the strength of the material at sites of damage. Such materials, which react to the application of mechanical force, and not light or heat, called mehanoforami.

During the experiments scientists have found out that the strength of the new plastic under load increases to 200 times compared with conventional. Invulnerability failed to reduce even a special solvent. When exposed at the side wall of the container, in which there was a solution formed plastic gel.

It is necessary to admit that this is not just another interesting experiment. Universal mehanofory like this can make a breakthrough not only in the smartphone market, but also in other areas. For example, medical prostheses, artificial valves, made of this material will be indispensable.

There is a strong likelihood that this development will still beyond the walls of the lab, but the researchers plan to create even more useful material. In order to create a high-impact plastic, which would have both properties such as softness and flexibility, they want to make the process of mechanical impact reversible.

Read another very interesting article about alternative energy of the Sun, water and air.